Basic Info.

Material: Electric galvanized wire, hot dipped galvanized wire, blue galvanized Weaving: Plain weaving This is the most commonly used style of weaving. Every second wire is woven in, warp and weft wires run over and under each other alternately and interlock. Plain weave wire meshes guarantee optimum accuracy of apertures of filter pores. Plain weave wire mesh use wires that are thinner than the corresponding apertures. Twilled weave stainless steel wire mesh:

In cases where increased wire thickness is required in relation to the aperture size, which yield in the weaving process cannot withstand, this style of weave is chosen. At least two wires are woven in pairs, subsequently displacing a single wire. Mesh stability is controlled by a combination of aperture size and wire strength, and displays a slight diagonal trend. Using moder weaving technology, excellent stability of weave can be achieved.

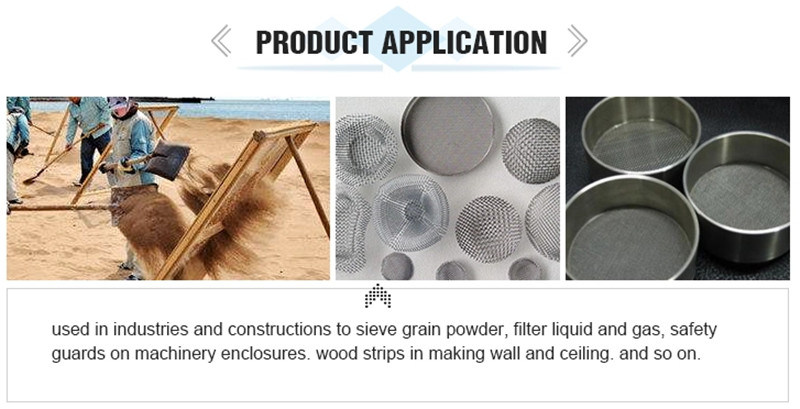

Width: 0.5-2m Length/roll: 15-100m customer's choice is avaliable. Mesh: 4*4-60*60mesh Wire diameter: 0.15-1.5mm All of the above can be made as customer's choice Application: Most used in window screening, industrial service in sugar, chemical, stone crusher industries, also in serving grain

It can be divided into two parts according to the different methods of galvanized: Hot dipped galvanized before or after weaving, electric galvanized before or after weaving End treatment: Cut end, closed end, weld after cut

| Mesh No | Wire | Size(Ft) |

| 1.5 | 1mm | 3 ×100,4 ×100,5 ×100 |

| 2 | 1mm-1.6mm | 3 ×100,4 ×100,5 ×100 |

| 3 | 0.6mm-1.6mm | 3 ×100,4 ×100,5 ×100 |

| 4 | 0.4mm-1.5mm | 3 ×100,4 ×100,5 ×100 |

| 5 | 0.35mm-1.5mm | 3 ×100,4 ×100,5 ×100 |

| 6 | 0.35mm-1.5mm | 3 ×100,4 ×100,5 ×100 |

| 8 | 0.3mm-1.2mm | 3 ×100,4 ×100,5 ×100 |

| 10 | 0.3mm-1.2mm | 3 ×100,4 ×100,5 ×100 |

| 12 | 0.2mm-1.2mm | 3 ×100,4 ×100,5 ×100 |

| 14 | 0.2mm-0.7mm | 3 ×100,4 ×100,5 ×100 |

| 18 | 0.2mm-0.6mm | 3 ×100,4 ×100,5 ×100 |

| 18 | 0.2mm-0.45mm | 3 ×100,4 ×100,5 ×100 |